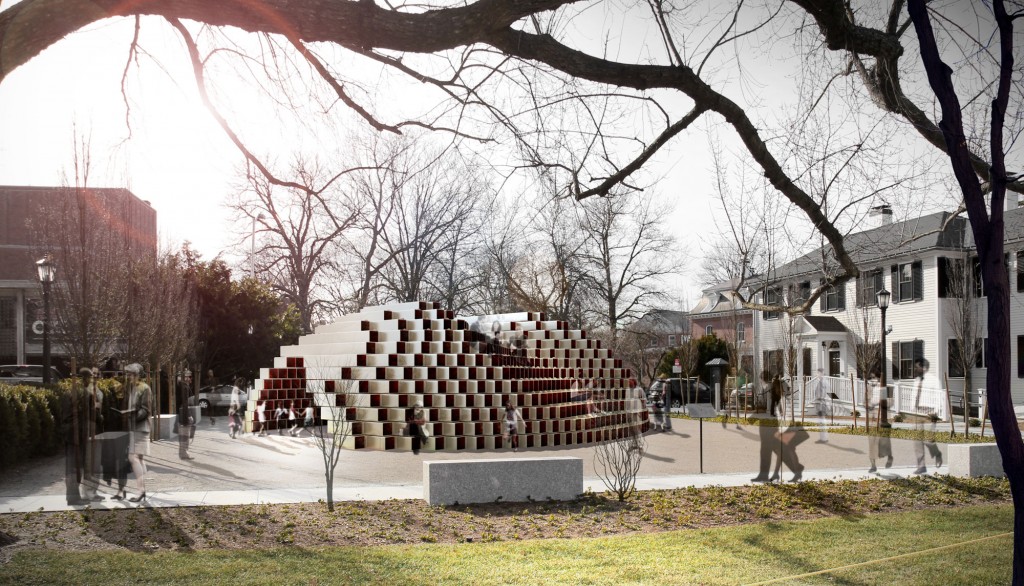

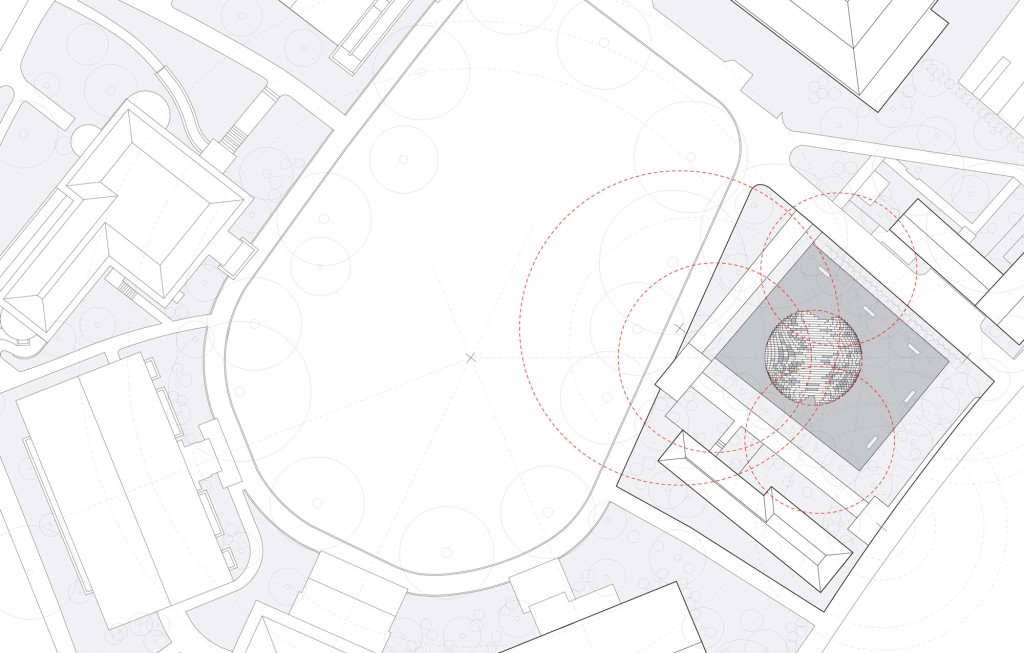

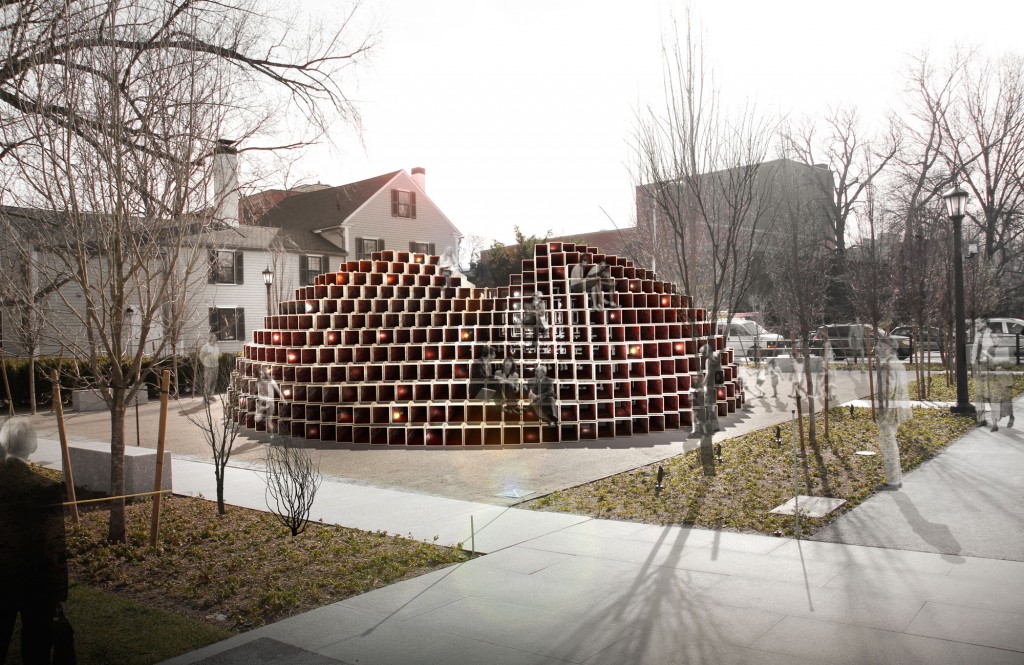

‘Re:stacked’ is a manufactured landscape from recycled materials, creating a responsive environment. It situates itself between the industrial and the playful. As a fundamental approach,‘Re:stacked’ acknowledges the integral relationship between the installation site and the overall Radcliff Institute site. Radcliff Yard is defined by a ring of buildings (solid) and the space between them (voids) that surrounds the perimeter of the yard. Although the existing empty installation lot acts as a void in this context, this relationship can either be maintained or converted depending on the nature of the installation. From this recognition, the pavilion transforms the site into a solid (object) in order to further enhance the boundary condition of the Radcliff Yard.

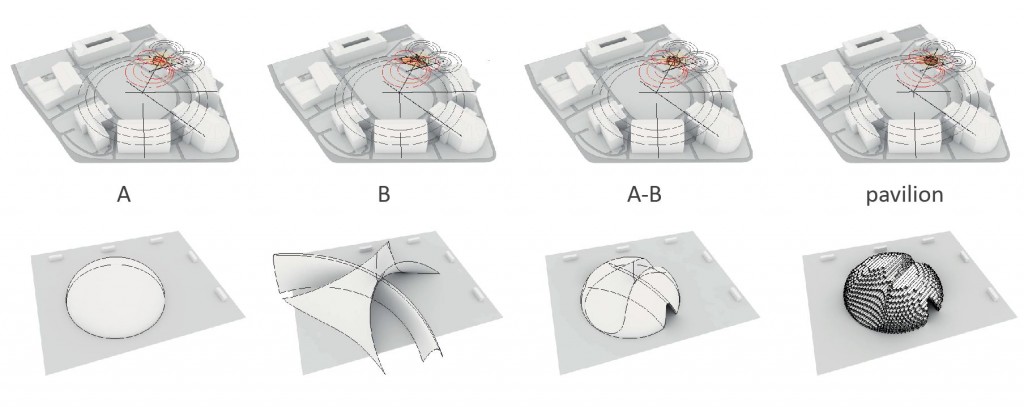

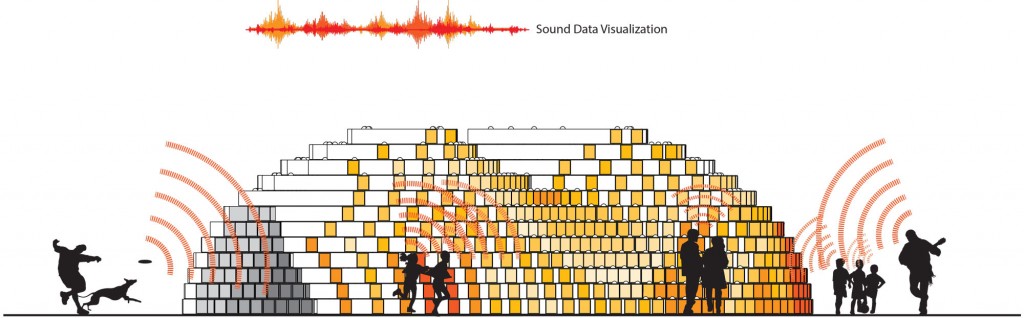

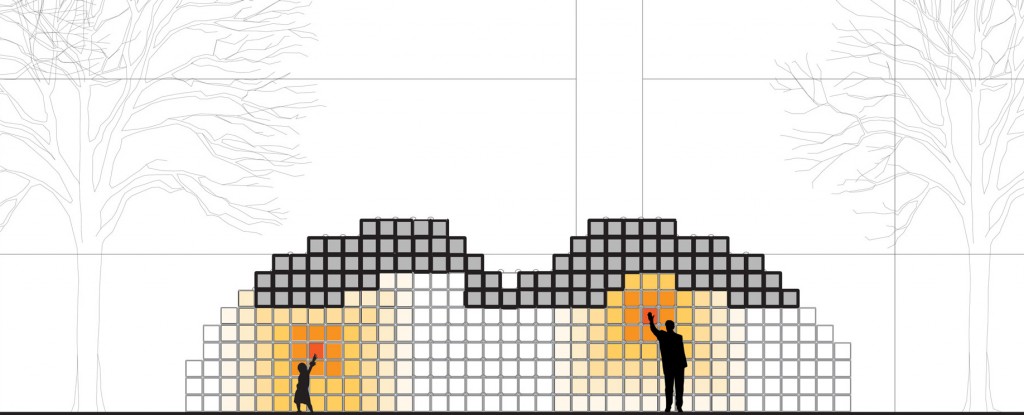

The geometric logic of Re:stacked is derived from the immediate vicinity of the site, strategically addressing it’s multi-directional nature and its relationship with the yard. Visual corridors, axial intersections, circles of impact that influence the overall form of the installation were generated using the center point of the Radcliff Yard as well as critical viewpoints from the adjacent roads. From the overall spherical massing of Re:stacked, two sweeping geometries are carved out in order to create two zones of activity: an outdoor theater and an exhibition tunnel. Each zone of activity is further augmented using programmable lighting embedded inside the installation components that responds to the environment and people (noise and proximity). In essence, creating a multi-sensorial responsive environment – audio, visual and tactile.

The key material and construction strategy of the installation is stacking salvaged steel tubes in the previously sculpted form. Post-tensioning elements will hold the tubes and ensure the structural integrity of the installation as well eliminate the need to drill into the steel tubes themselves. This strategy will allow the installation to be dismantled and sold back to the salvage yard for re-usage. The design will be accounted for the specific variety of tubes found at the local salvage yard and using the developed parametric script the design team will collect salvage data and the design will ‘automatically’ adjust to a given set of as measured components.