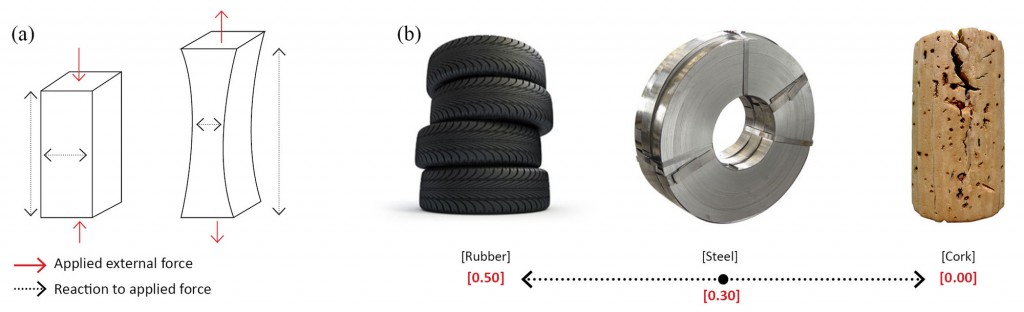

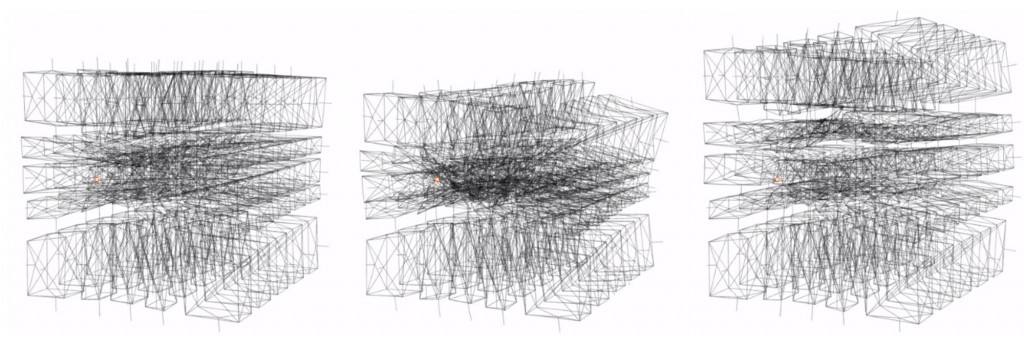

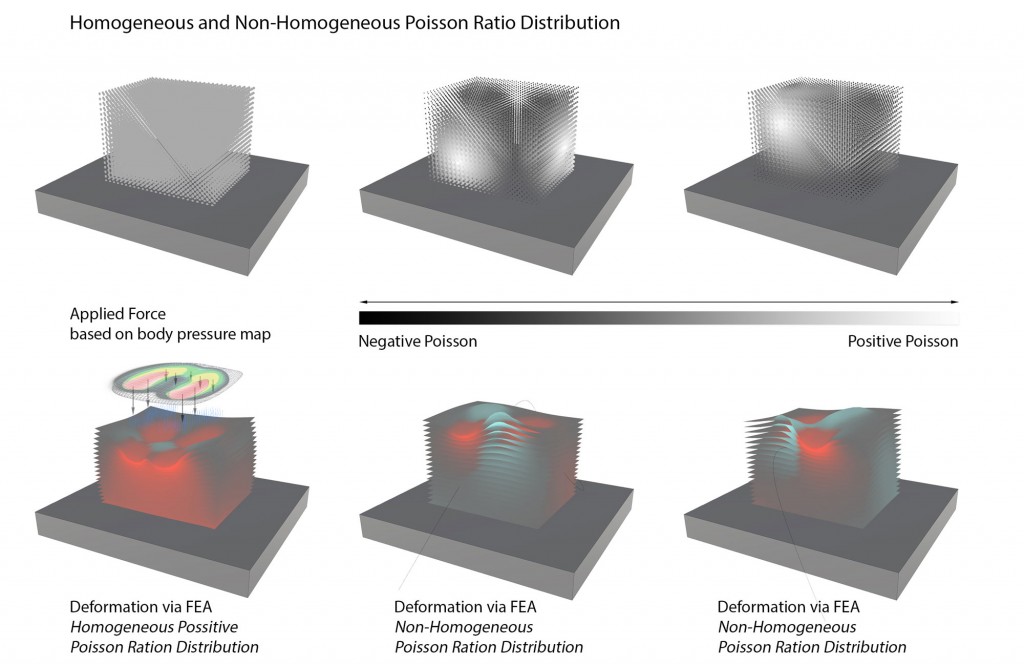

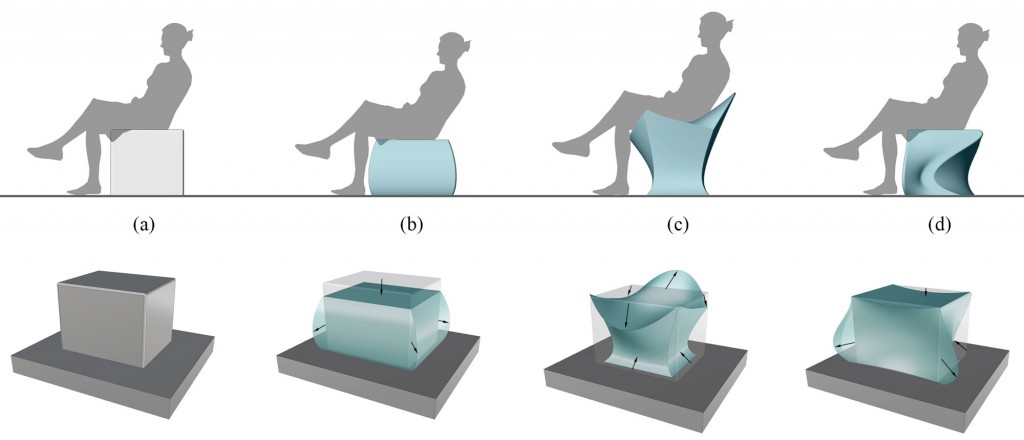

This research derives from the notion that in all of these cases, the unusual material behavior can be understood through the geometry of its microstructure and the geometrical adaptations resulting from applied loads. Stemming from the cellular architecture of materials, this study proposes 2D and 3D designs of cell configurations highlighting the impact that cell geometry and relative density can have on structure mechanical properties. Samples of material distributions are both fabricated and digitally simulated. Following a cumulative methodology, this investigation takes place in three stages: 2D topology studies, single cell compliant mechanism studies and 3D topology studies considering future manufacturing with multi-material additive processes. Each stage of physical and virtual prototyping and testing had specific objectives and procedures mentioned above and hence, revealed separate meaningful results. From the heterogeneous 2D topology study, it was possible to achieve a wide range of non-linear and non-uniform deformation at the global level (overall shape of the sample) using relatively simple and linear transformation of cells. On the other hand, the single cell compliant mechanism studies, which implements non-linearity into the cell itself, drastically expands the geometric diversity in addition to attaining more complex and systematic global deformation. Finally, the 3D topology studies presents a plethora of opportunities relating to design and engineering applications by verifying that the heterogeneous 2d topology can be successfully applied to 3D geometries. Through this research we have proposed two and three dimensional geometry to engineer and simulate customized classical and auxetic homogeneous and heterogeneous material distributions. Extension to further practical design applications is currently in progress.

Poisson Distribution

Information

- Date: May ,2013

- Collaboration with Ale Romo and Juhun Lee

- Advisor: Panagiotis Michalatos

Publication

- Park, Daekwon, Ale Romo, and Juhun Lee. 2015. “Poisson’s Ratio Material Distribution.” Proceedings of the 20th International Conference of the Association of Computer-Aided Architectural Design Research in Asia (CAADRIA) – Emerging Experiences in the Past, Present and Future Digital Architecture.

Award

- Best Paper Award Runner-up, Computer-Aided Architectural Design Research in Asia (CAADRIA), 2015

- Young CADDRIA Award, Computer-Aided Architectural Design Research in Asia (CAADRIA), 2015

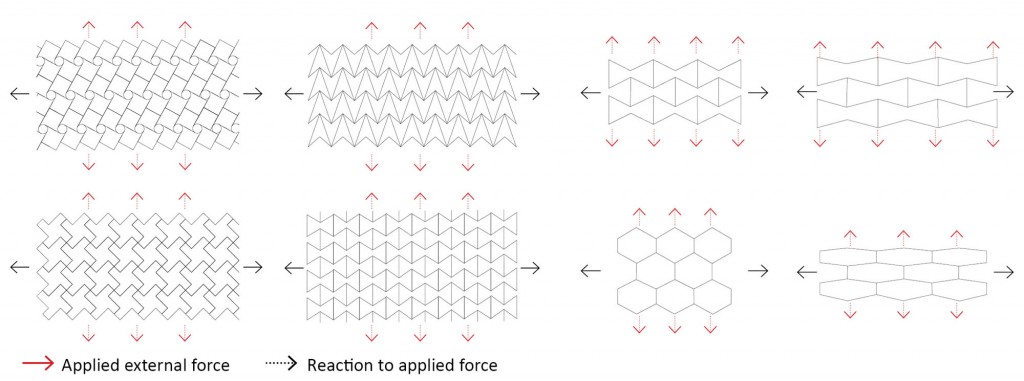

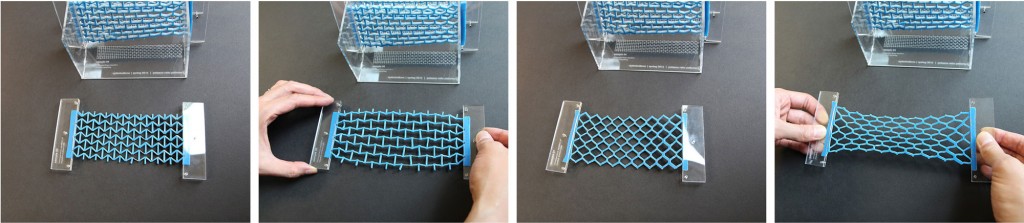

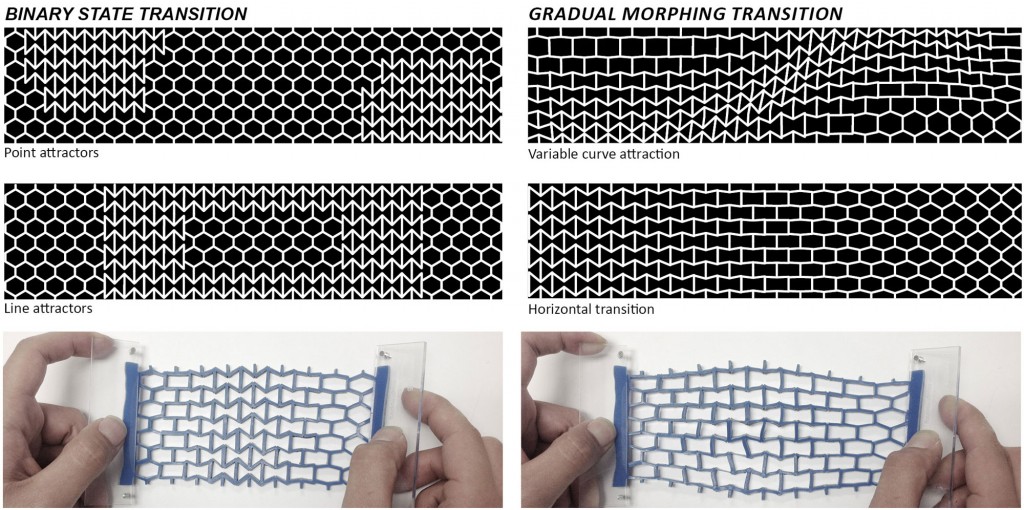

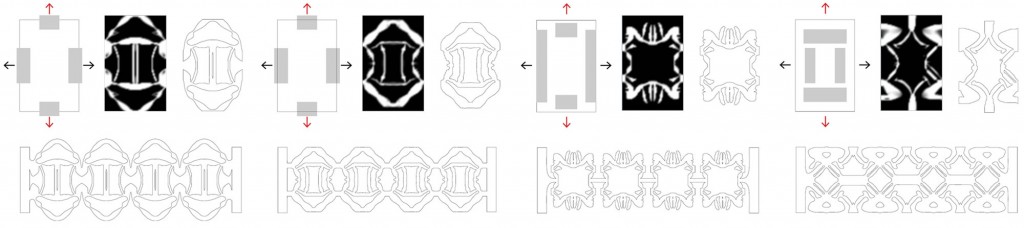

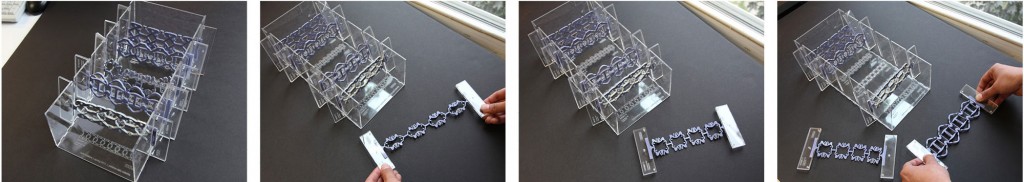

The 2D topology studies are sub-divided into two categories: two state transition and gradual morphing. Both approaches center on the challenge of finding a connection between heterogeneous networks and its material properties from a new perspective. Within the two state transition study, one positive and one negative poisson cell prototypes are replicated and configured following proximity attraction to an object resulting in engineered customization of stiffness and elasticity.

Building on the principle of this heterogeneous 2D topology, the gradual morphing study deforms and replicates initial negative and positive poisson cells producing a finer grained customization of mechanical properties. From the principle that a single geometrical cell constitutes the building block of these topological constructs, the next study performs a series of single cell analysis embedding compliant mechanism material optimizations. Applying the millipede Grasshopper™ component, a series of 2D periodic and non-periodic cells are generated and simulated.

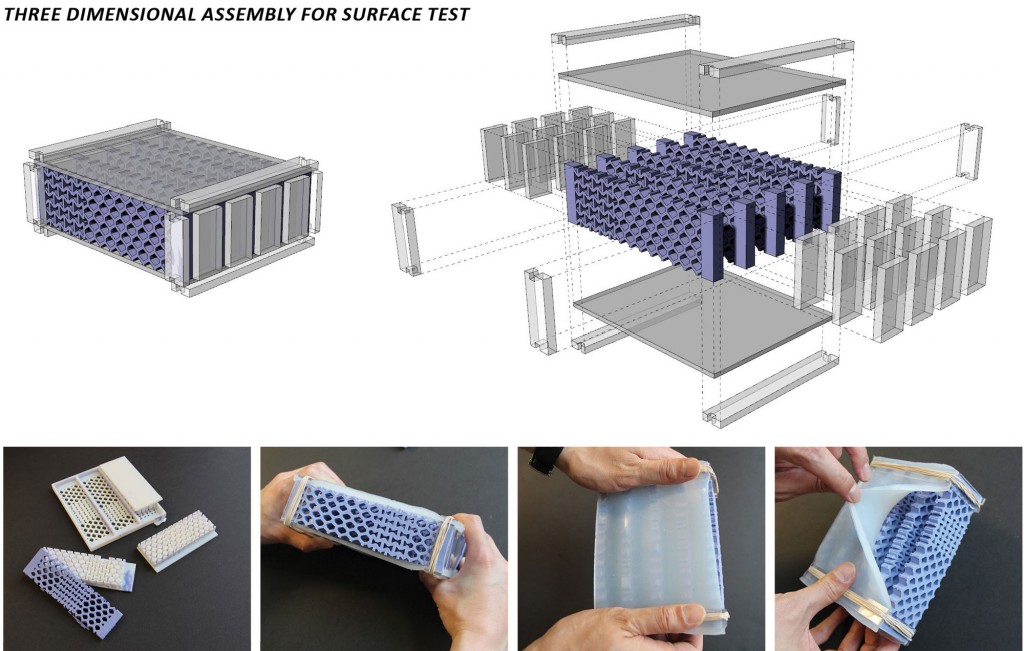

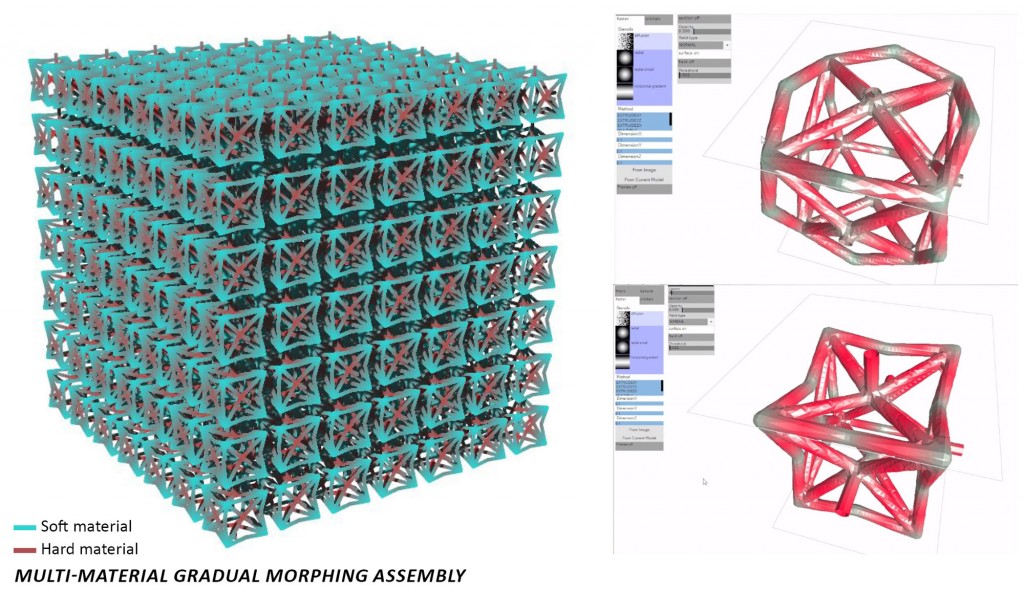

The final stage of this study builds on the gradual morphing of negative and positive cells to produce 3D compositions. Considering multi-material additive manufacturing, each cell within the heterogeneous composition is customized with both hard and soft material properties transitioning from flexible joints to stiff struts.

Each stage of physical and virtual prototyping and testing had specific objectives and procedures mentioned above and hence, revealed separate meaningful results. From the heterogeneous 2D topology study, it was possible to achieve a wide range of non-linear and non-uniform deformation at the global level (overall shape of the sample) using relatively simple and linear transformation of cells. On the other hand, the single cell compliant mechanism studies, which implements non-linearity into the cell itself, drastically expands the geometric diversity in addition to attaining more complex and systematic global deformation. Finally, the 3D topology studies presents a plethora of opportunities relating to design and engineering applications by verifying that the heterogeneous 2d topology can be successfully applied to 3D geometries. Through this research we have proposed two and three dimensional geometry to engineer and simulate customized classical and auxetic homogeneous and heterogeneous material distributions. Extension to further practical design applications is the subject of potential future investigation.