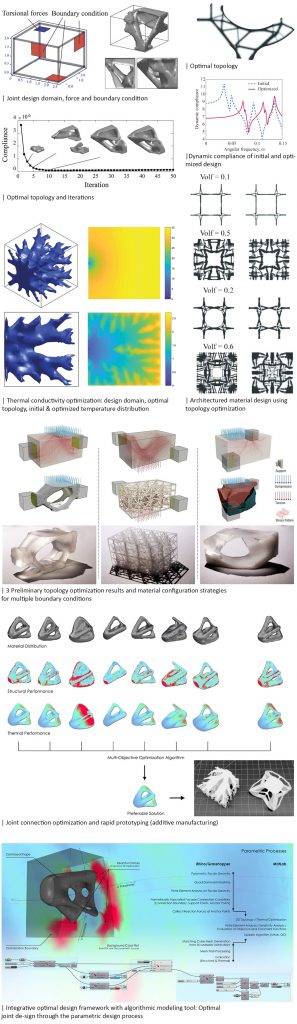

Joints and connectors are often the most complex element in building assemblies and systems. To ensure the performance of the assemblies and systems, it is critical to optimize the geometry and configurations of the joints based on key functional requirements (e.g., stiffness and thermal exchange). The proposed research focuses on developing a multi-objective topology optimization framework that can be utilized to design highly customized joints and connections for building applications. The optimized joints that often resemble tree structures or bones are fabricated using additive manufacturing techniques. This framework is built upon the integration of high-fidelity topology optimization algorithms, additive manufacturing, computer simulations and parametric design. Case studies and numerical applications are presented to demonstrate the validity and effectiveness of the proposed optimization and additive manufacturing framework. Opti-mal joint designs from a variety of architectural and structural design considerations, such as stiffness, thermal exchange, and vibration are discussed to provide an insightful interpretation of these interrelationships and their impact on joint performance.

Topo-Joint

SPONSOR

- Syracuse Center of Excellence

COLLABORATORS

- Junho Chun (Syracuse SoA)

- Juhun Lee (Simpson Gumpertz & Heger)

PUBLICATIONS

- Chun, J., Park, D., Lee, J. 2019. TOPO-Joint: Reliability-based topology optimization for 3D-printed building joints. International Conference on Applications of Statistics and Probability in Civil Engineering 2019, Seoul, South Korea.

- Chun, Junho, Lee, Juhun, and Park, Daekwon. 2018. “Topo-Joint: Topology Optimization of 3d Printed Hybrid Materials for Building Joint Applications.” Proceedings of the 23rd International Conference of the Association of Computer-Aided Architectural Design Research in Asia (CAADRIA), Beijing, China.