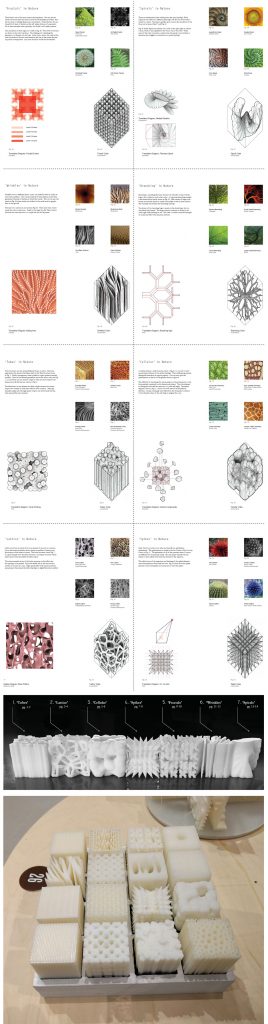

The research conducted follows two main output goals. First, to understand digital fabrication using 3d printing technology. 3d printing will continue to emerge and engage larger scales in architectural design. These small studies of 4cm cubes are the beginnings of what could be larger-scale products using the same parameters. Contrary to popular belief, 3d printing cannot output any high-quality formal aspiration. One must understand the logic of this fabrication technique, how the 3d printer lays material, and how the digital model affects the physical result. An entry point to the conversation of digital fabrication was the infusion of Biotectonic. Digital fabrication frees previously rigid guidelines which allow the designer to have more freedom in form. This study looks at organic patterns that occur in nature for formal inspiration. These challenging, and often algorithmic, patterns lend themselves to digitally-driven design. Eight separate forms found in nature were regulated to a cube to test the translation from organic to digital to a fabricated study. This booklet documents the form-finding process of studying nature patterns followed by the translation logic used to create the digitally fabricated cubes. (Text by Philip Claghorn)